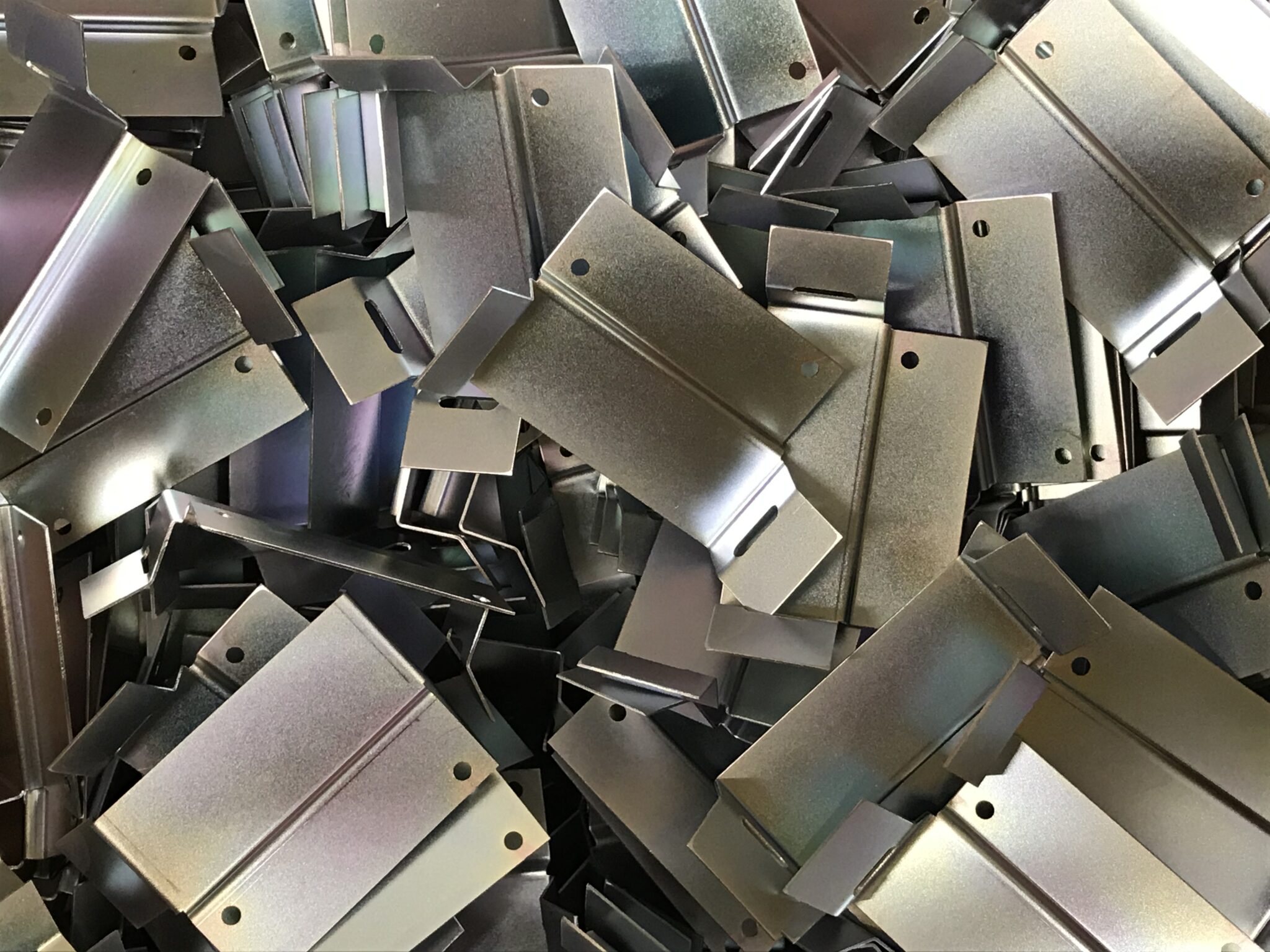

Sheet metal brackets play a crucial role in structural support, machinery, and countless industrial applications. The design of these brackets directly impacts the durability, safety, and efficiency of the final product. Precision in sheet metal bracket design ensures that structures remain robust and reliable over time, reducing maintenance costs and enhancing overall performance.

Importance of Precision in Bracket Design

A well-designed sheet metal bracket delivers stability and strength, supporting loads accurately while resisting wear and deformation. Precision ensures that each component fits seamlessly, which is essential in assemblies where alignment is critical. Designers often revisit sheet metal bracket design to reduce costs while maintaining structural integrity. Key benefits of precision design include:

- Enhanced Structural Integrity: Accurate dimensions reduce stress points and improve load distribution.

- Reduced Material Waste: Optimized designs minimize excess material, promoting cost efficiency.

- Improved Safety: Correctly designed brackets prevent failures and accidents in industrial applications.

Advanced Design Techniques

Modern fabrication relies on innovative techniques that combine engineering principles with advanced machinery. Precision bracket design often involves:

- Computer-Aided Design CAD: CAD software allows engineers to visualize complex geometries and test structural performance before production.

- Finite Element Analysis FEA: FEA identifies stress concentrations and potential failure points, ensuring optimal strength.

- 3D Prototyping: Rapid prototyping enables testing and adjustments to design before committing to full-scale manufacturing.

These techniques collectively ensure that brackets are both strong and lightweight, maximizing their functional efficiency without compromising durability.

Material Selection for Longevity

The performance of a sheet metal bracket is not only defined by design but also by the materials used. Choosing high-quality metals with appropriate thickness and surface treatments enhances longevity and resistance to corrosion. Advantages of proper material selection include:

- Durability Under Stress: Strong metals withstand heavy loads and continuous use.

- Corrosion Resistance: Protective coatings or stainless steel prevent rust and degradation.

- Consistent Performance: High-quality materials maintain structural integrity across various environmental conditions.

Precision Manufacturing Processes

Beyond design, precise manufacturing processes are essential to achieve the intended performance. Techniques such as laser cutting, CNC punching, and robotic bending ensure that each bracket meets exact specifications. Partnering with precision sheet metal fabrication companies guarantees reliable and precise component manufacturing. The advantages include:

- Consistent Quality: Automation minimizes human error, delivering reliable brackets every time.

- Tight Tolerances: High accuracy ensures perfect fitment in assemblies, improving overall operational efficiency.

- Cost Efficiency: Precision manufacturing reduces rework, scrap, and production delays.

Conclusion

Precision sheet metal bracket design is integral to creating long-lasting, reliable components. By combining careful engineering, high-quality materials, and advanced manufacturing methods, these brackets deliver exceptional performance and structural stability. Businesses and industries benefit from reduced maintenance costs, enhanced safety, and operational efficiency. Investing in precision design ensures that sheet metal brackets continue to support structures effectively for years to come.

Key Takeaways:

- Precision enhances strength, safety, and durability.

- Advanced design techniques like CAD and FEA optimize bracket performance.

- High-quality materials resist corrosion and wear.

- Precision manufacturing ensures consistent, reliable results.